Industry news|2022-05-19| admin

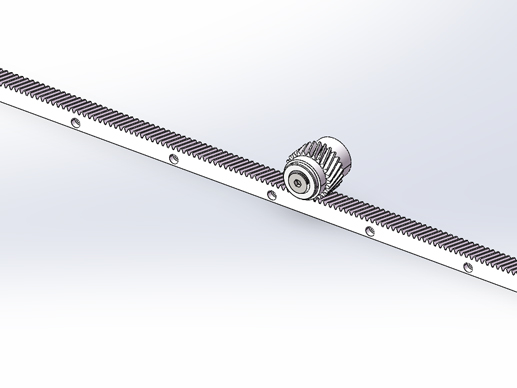

With the popularization of rack and pinion applications, rack and pinion are widely used in laser cutting, gantry machine tools, machining centers, woodworking machinery, etc.; the requirements for rack and pinion products are constantly improving, especially for some long strokes, heavy loads and high precision. The application of such requirements is increasing. However, in the application of rack and pinion, many people do not know much about the selection, and they are worried that in the selection process, if the selection is too small, it will not be useful, and the selection will be wasteful. Here it needs to be clear which parameters will affect the selection result. Generally speaking, the load torque is the most basic, but there are distinctions, rated torque and acceleration; it is also necessary to pay attention to the parameters of axial force, radial force, and tilting moment, which will affect the life of the mounted reducer; There are also parameters such as transmission efficiency, friction force, external force, safety factor, gearbox's own friction torque, motor inertia and other parameters. The larger the equipment, the more detailed calculation it should be. What parameters are required for rack and pinion selection?

1. Tooth shape: whether it is a straight tooth or a helical tooth. The straight tooth transmits a larger torque, but the relative noise is also large.

2. Module: The module is a basic parameter of the rack and pinion, ranging from 1.5 module to 8 module. Generally, when the number of teeth is the same, the larger the module is, the larger the gear will be. When the module is the same, the The larger the number of teeth, the larger the gear, the larger the module of the rack, the larger the rack, the stronger the bearing capacity, but considering the cost, the bigger is not the better, and the appropriate gear needs to be selected according to the load situation. Rack module and number of teeth.

3. Accuracy grade: According to the load conditions and equipment accuracy requirements during model selection, the optional accuracy grades of the rack are 6, 6S, 8, 9, etc., of which 6 and 6S are ground racks. The pitch line error with an accuracy of 1000mm is less than 0.020~0.025, and the 8th and 9th grades are precision milling racks, which can be used in equipment that does not require precision.

4. Length: The standard length of the rack is 1000mm, which can be spliced infinitely